Form developed with Volume Studio

PHOTOGRAPHY MODEL

This model was used on packaging and apart from the pedals, this in-house model is entirely finished and fabricated with 3D printed parts, custom welded metal frame and crank fabrication by our amazing shop talent. Note: that front tire was printed in my basement as a test part in TPU.

USER TESTING

Earlier smaller wheeled prototypes were tested with users of different ages. From these tests we decided on larger wheels and a wider tire as well as some more needed strengtheining

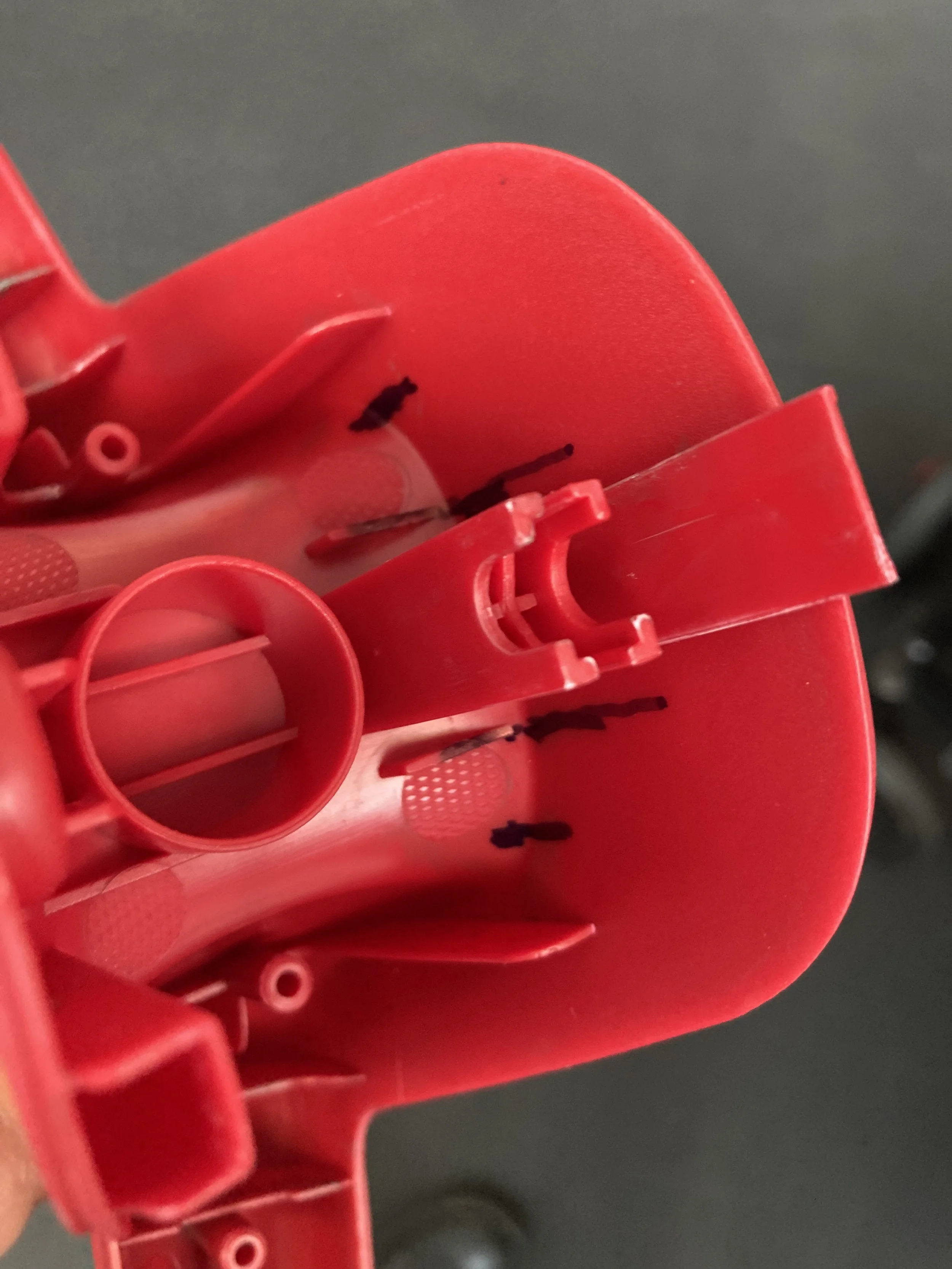

PACKOUT EXPLORATION & ASSEMBLY OPTIMIZATON

Throughout the development, we were always evaluating the packout to see how few assembly steps we could achieve and also maintain an Amazon shipping standard should we ever need it.

COMPLIANCE

We worked to meet all toy standards including those for tricycles in China, which required a minimum clearance for the pedal (shown) when the handle is turned to its limit.

ARTWORK & WARNINGS

Carton artwork, instruction layout and illustration, warnings and textures all needed to be managed and signed off on. This is engineering pilot model for review that did not yet have all of its texture applied.

PRODUCTION DEBUG

Reviewing all of the details of the pilot production parts. Left to right: reviewing the replacement parts and procedure with Quality Assurance and Customer Service for sending and installing a replacement back wheel, then suggesting location for additional rib structure for better drop test result, and finally illustrating to the manufacturing engineers why we needed drain holes in the seat to prevent sitting water.